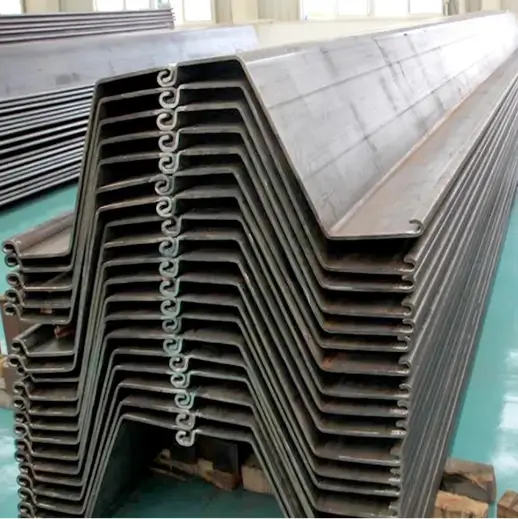

Z-type steel sheet piles are made of building materials, and their locking openings are symmetrically distributed on both sides of the neutral axis. Coupled with the continuity of the web, the cross-sectional modulus of the steel sheet piles is greatly improved, ensuring that the mechanical properties of the cross-section are fully utilized.

Z-type steel sheet piles are widely used in fields such as automobiles, railway vehicles, shelves, electrical cabinets, highway guardrails, building steel structures, containers, transmission towers, steel sheet piles, cable trays, agricultural machinery, furniture, vegetable greenhouses, pipeline supports, etc.

The Z-type steel sheet pile is sunk by vibrating Pile driver, with fast construction speed and better pile pulling effect. Compared with the construction of impact Pile driver, the noise is low, the pile top is not easily damaged, the operation is simple, and there is no smoke generated by diesel or steam hammer construction. The principle of the vibrating Pile driver is to transmit the vertical vibration generated by the machine to the pile body, reduce the resistance around the Z-type steel sheet pile, and facilitate the penetration of the sheet pile.

Explanation of Z-type steel sheet pile: The locking mouth is symmetrically distributed on both sides of the neutral axis, and the web is continuous, which greatly improves the section modulus and bending stiffness, ensuring that the mechanical properties of the section can be fully utilized. Due to its unique cross-sectional shape and reliable Larsen lock.

Z-type steel sheet piles have the following advantages:

- Flexible design with relatively high cross-sectional modulus and mass ratio;

- A higher moment of inertia increases the stiffness of the sheet pile wall and reduces displacement deformation;

- Wide width, effectively saving time for lifting and piling;

- The increase in section width reduces the number of shrinkage joints in the sheet pile wall, directly improving its water sealing performance;

- Thickening treatment has been carried out on severely corroded areas, resulting in better corrosion resistance.

feature:

- The section width is large, and the pile sinking effect is significant.

- The cross-sectional modulus is large.

- The higher moment of inertia enhances the stiffness of the steel sheet pile wall and reduces structural deformation.

- Excellent corrosion resistance.

The cold-formed Z-type steel sheet pile product has the characteristics of convenient construction, fast progress, no need for large construction equipment, and is conducive to seismic design in civil engineering applications. It can also change the cross-sectional shape and length of the cold-formed Z-type steel sheet pile according to the specific situation of the project, making the structural design more economical and reasonable. In addition, through the optimization design of the cross-section of the cold-formed steel sheet pile product, the quality coefficient of the product has been significantly improved, reducing the weight per meter of pile wall width and reducing engineering costs.

Production scope of Z-type steel sheet pile:

Thickness: 4-16mm

Length: unlimited or according to customer requirements

Other: Customized sizes and designs can be provided, and anti-corrosion can be provided.

We have also launched Z-type steel sheet pile support with widths of 800mm and 850mm, which saves more materials when reaching the same performance parameters.

Materials: Q235B, Q345B, S235, S240, SY295, S355, S430, S460, A690, ASTM A572 Grade 50, ASTM A572 Grade 60, as well as all national, European, and American standard materials suitable for producing Z-type steel sheet piles.

Product manufacturing inspection standards: national standard GB/T29654-2013, European standard EN10249-1/EN10249-2.