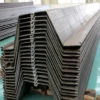

Steel sheet pile products are divided into two categories according to production processes: cold-formed thin-walled steel sheet piles and hot-rolled steel sheet piles. There are two types of cold-formed steel sheet piles: non occluded cold-formed steel sheet (also known as groove plate) and occluded cold-formed steel sheet (divided into L-type, S-type, U-type, Z-type). Production process: Continuously rolling thin steel plates on a cold bending machine (commonly used thickness is 8mm~14mm).

U-type steel sheet piles are easy to drive into hard soil layers; Construction can be carried out in deep water, and if necessary, inclined supports can be added to form a cage. Good waterproof performance; It can form various shapes of cofferdams as needed and can be reused multiple times.

U-type steel sheet pile refers to hot-rolled steel sheet pile, which is a type of pile with connecting devices at the edge.

Steel sheet piles have a type of steel with a locking mouth. Its cross-section is straight, grooved, and Z-type. It comes in various sizes and interlocking forms. Common types include Larsen type, Lachwana type, etc. These steel sheet piles can be freely combined to form a continuous and compact retaining wall or retaining wall steel structure.

The production process of U-type steel sheet piles is mainly achieved through high-temperature rolling of the section steel mill. It has a special size, superior performance, reasonable cross-section, high quality, and waterproof locking. Disadvantages include high technical difficulty, high production costs, and inflexibility in specifications and series.

Explanation of U-type steel sheet pile:

- 1.The cross-sectional structure design of U-type steel sheet piles is reasonable, and the forming process technology is advanced. The ratio of cross-sectional modulus to weight of steel sheet pile products has been continuously improved, achieving good economic benefits in application and expanding the application field of cold-formed steel sheet piles.

- There are various specifications and models of U-typesteel sheet piles, and the most economical and reasonable section can be selected according to the actual situation of the project to achieve optimization of engineering design. Compared with hot-rolled steel sheet piles with the same performance, it saves 10-15% of materials and greatly reduces construction costs.

- Designed and produced according to European standards, a symmetrical structural form is conducive to reuse, equivalent to hot rolling in terms of reuse, and has a certain angle amplitude, making it easy to correct construction deviations;

- The use of high-strength steel and advanced production equipment ensures the performance of cold-formed steel sheet piles;

- The length can be customized according to customer requirements, bringing convenience to construction and reducing costs.

- Due to convenient production, when used in conjunction with composite piles, they can be pre ordered before leaving the factory.

- The production design and production cycle are short, and the performance of steel sheet piles can be determined according to customer requirements.

Cold formed U-type steel sheet piles were introduced at the end of the 20th century. Compared with traditional Larsen steel sheet piles, cold-formed U-type steel sheet piles have the following advantages:

- Low weight per square meter. When providing equal or higher product performance, a lower quantity of steel is used, saving material costs.

- Wider width. Under the same project, the number of steel sheet piles was reduced, thereby accelerating the construction and driving speed, and saving manpower and equipment costs.

- Uniform thickness. Traditional hot-rolled steel sheet piles usually have uneven thickness, only showing the thickest part, and the locking part is very thin, which is easily damaged during the pile driving process. The uniform thickness of cold-formed steel sheet piles makes them more stable during the pile driving process and can be reused multiple times.

U-type steel sheet piles are usually transported as single piles and do not require assembly. In some designs, U-type steel sheet piles can also be transported as box type steel sheet piles.