| Product Name | Galvanized Steel Sheet |

|---|---|

| Standard and Materia | SGCC;SGCD1;SGCD2;SGCD3;SGC340;SGC400;SGC440;SGC590; |

| DX51D+Z;DX52D+Z;DX53D+Z;DX54D+Z;S250GD+Z; | |

| S280GD+Z;S320GD+Z;S350GD+Z;S550GD+Z;Q-BQB420-2009 | |

| Thickness | 0.13-0.8mm |

| Width | 600-1250mm |

| Zinc coating | 20- 275g/m2 |

| Coil Weight | 3-8 Tons or as requirment |

| Surface Treatment | Mini/Big Spangle |

| Application | Applies to construction field,ships building industryboiler heat exchangerpetroleum chemical industries war and electricitvindustries,food processing and medical industrymachinery and hardware fields. |

| Payment | T/T, L/C, Western Union |

| Packing method | Water proof paper+wooden pallets or as requirements |

Part 1 Product description

Hot dip galvanized products are widely used in construction, home appliances, vehicles and ships, container manufacturing, mechanical and electrical industries, and almost involve various fields such as clothing, food, housing, and transportation. In recent years, the demand for galvanized steel plates in the world has been continuously increasing, and the production has also grown rapidly. In major steel producing countries such as the United States and Japan, the proportion of hot-dip galvanized steel plates in steel has reached 13% -15%.

Recently, the automotive industry has increasingly attached importance to the service life of materials, and using painted cold-rolled steel plates can no longer meet the requirements for corrosion resistance. In this situation, hot-dip galvanized sheets with excellent corrosion resistance and low cost have become widely favored by automotive manufacturers.

Part 2 advantage

The biggest advantage of coated steel plates is their excellent corrosion resistance, paint resistance, decorative properties, and good formability. In recent years, the usage of coated steel plates in automobiles has been on the rise and has become the main body of automotive thin plates. Countries around the world are studying how to expand the variety and specifications of coated laminates, improve coating processes, and improve coating quality, including corrosion resistance, resistance to powdering and peeling, coating performance, and weldability. The formability of coated plates has always been an important aspect of their application, which mainly depends on the substrate performance, coating process and performance, and forming process conditions. By combining comprehensive advanced technologies, good application results can be achieved.

Part 3 High-quality

The quality requirements for high-quality galvanized sheet include specifications, dimensions, surface, galvanizing amount, chemical composition, sheet shape, machine function, and packaging.

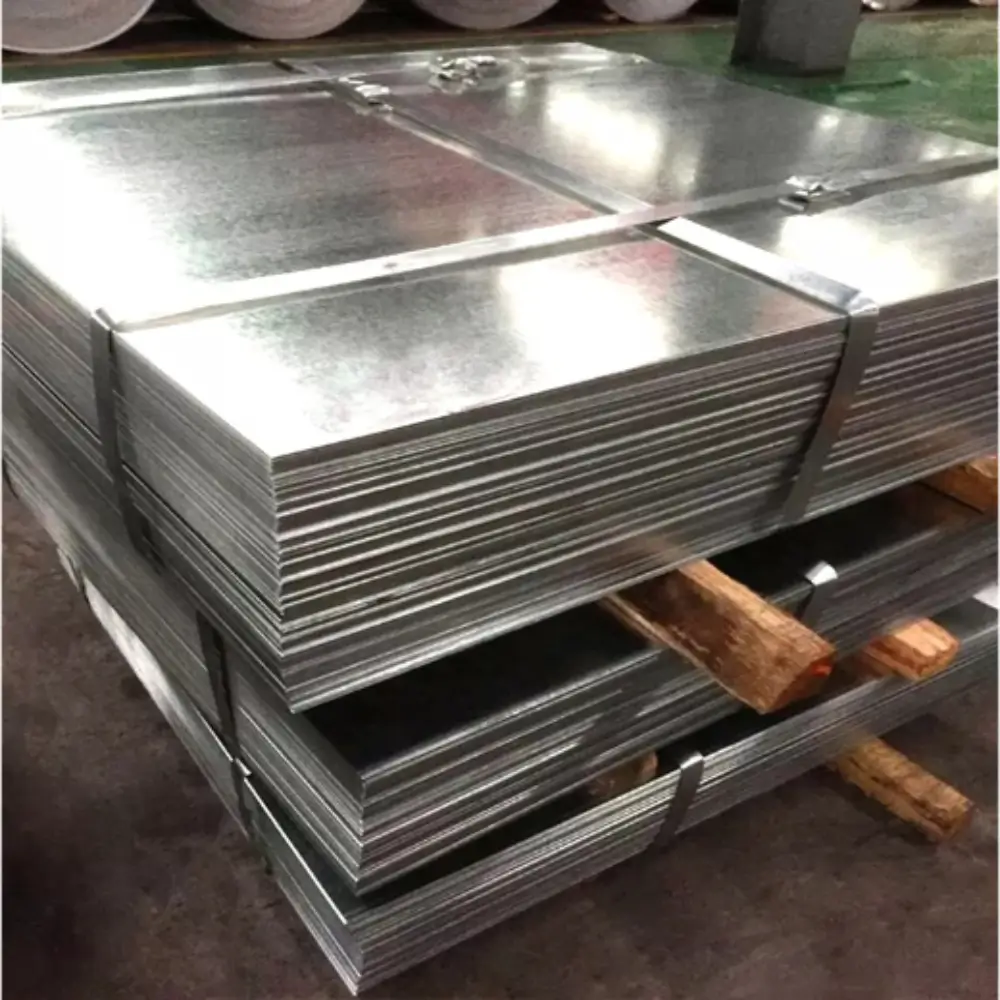

1. Packaging

There are two types of packaging: galvanized sheet cut into fixed lengths and galvanized sheet with coils. General iron sheet packaging, lined with moisture-proof paper, tied with an iron waist outside, securely fastened to prevent friction between the galvanized plates inside.

2. Specifications and dimensions

The recommended dimensions, thickness, length, and width of the galvanized sheet, as well as their allowable defects, are listed for the product scale (such as the following and). In addition, the width and length of the board, as well as the width of the roll, can also be determined according to user requests.

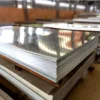

3. Surface

Overview: Due to different disposal methods in the coating process, the overview of galvanized sheet is also different, such as the overview of ordinary zinc flakes, fine zinc flakes, flat zinc flakes, zinc free flakes, and phosphating treatment. Galvanized sheets and galvanized coils cut to a fixed length shall not have any defects that affect their use (as described below), but the coils shall allow for welding parts and other non deformed parts.

4. Galvanizing quantity

Scale value of zinc plating amount: Zinc plating amount is a widely adopted and useful method to indicate the thickness of the zinc layer on galvanized sheets. There are two types of galvanization: identical galvanization on both sides (i.e. equal thickness galvanization) and different galvanization on both sides (i.e. differential thickness galvanization). The unit of galvanizing quantity is g/m.

5. Machine functions

(1) Tensile test

Generally speaking, as long as galvanized sheets for layout, stretching, and deep stretching have tensile strength requirements.

(2) Bending experiment

It is an important term for balancing the process function of thin plates. However, the requirements for various types of galvanized sheets vary among different countries. Generally, after the galvanized plate is bent 180 degrees, there should be no zinc layer left on the outer surface, and the plate base should not have cracks or fractures.

6. Chemical composition

There is disagreement among countries regarding the requirements for the chemical composition of galvanized substrates. If Japan does not request, the United States requests. Generally, product inspection is not conducted.

7. Plate shape

There are two goals for balancing black and white plate shape, namely flatness and sickle bending. The flatness of the board and the maximum allowable value of sickle bending are specified.