Introduction

Angle iron is an extremely versatile and versatile building material that has stood the test of time. With its unique L-shaped profile and exceptional durability, however, it offers several advantages for a variety of applications. In this blog, we take a deep dive into the world of angle iron and explore its many uses in different industries. Additionally, we’ll discuss the various factors that make angle irons sizes the top choice for professionals looking for reliable structural support and versatility. So, let’s delve into the incredible possibilities of angle iron!

Part 1 What is Angle Iron?

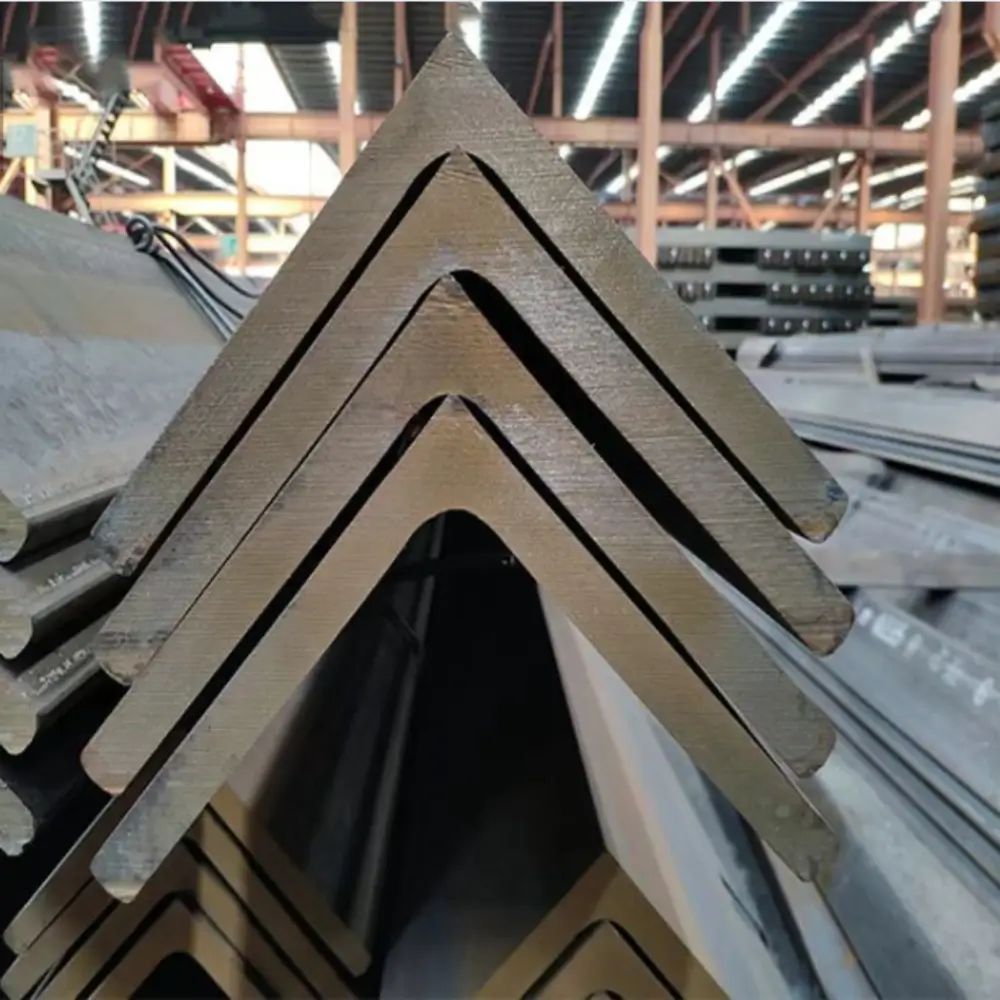

Angle steel is a rolled steel or iron structural profile with an L-shaped cross-section. Therefore, it is formed by bending a piece of iron or steel at a 90-degree angle, forming two equal-sized legs. The width and thickness of the legs can vary according to the specific requirements of the project. Angles are available in hot-rolled or cold-rolled varieties and can be made from different materials such as carbon steel, stainless steel or aluminium.

Part 2 Application of Angle Iron

Angle irons are widely used in various industries due to their superior strength and versatility. Here are some key applications:

1. Structural support

Angle iron is an indispensable element in architectural and engineering projects, providing firm support for beams, columns and trusses. It provides extra strength to the frame and ensures the stability and longevity of the structure.

2. Shelving and Shelving Systems

Angle irons are an essential part of creating strong and adjustable shelving and shelving systems. Its rigid structure allows the rack to withstand heavy loads without bending or warping.

3. Vehicle Frames

From bicycles to automobiles, angle irons are used to create durable and resilient frames for various modes of transportation. Its reliable strength ensures the safety and stability of the vehicle.

4. Fences and gates

Angle iron is often used to build strong fences and gates. Meanwhile, it provides support, enhances security and withstands external forces, providing a durable solution for perimeter protection.

5. Furniture Manufacturing

Because of its structural integrity and aesthetics, angle irons are widely used in the manufacture of furniture such as tables, bed frames, and chairs. Its versatility allows numerous design possibilities.

6. DIY projects

Angle iron is a favorite material for DIY enthusiasts. Its ease of use, affordability and adaptability make it ideal for projects such as shelving units, stands and custom furniture.

Part 3 Advantages of Angle Iron

The popularity of angle iron can be attributed to its numerous advantages. Some notable benefits include:

1. Strength and Durability

Angle irons provide exceptional strength and durability, ensuring long-term structural integrity.

2. Versatility

Its L-shaped design can be easily connected, welded and bolted, making it suitable for various applications.

3. Cost-Effective Solution

Angle irons are a cost-effective option and are worth the money due to their long lifespan and minimal maintenance requirements.

4. Resistant to environmental factor

Angle iron is resistant to corrosion, fire and extreme weather conditions, suitable for indoor and outdoor applications.

Part 4 Several Common Angle Steel Sizes

Angle irons, available in diverse sizes such as 75 x 8 angle iron, 65 x 8 angle iron, and 25 x 1 8 angle iron, are essential components in construction, manufacturing, furniture, and agricultural industries due to their strength, versatility, and cost-effectiveness. From providing structural support to enhancing stability, so, these angled steel bars play a vital role in countless projects. By understanding the different sizes and applications of angle irons, professionals can make informed decisions when selecting the ideal materials for their specific needs.

a. 75 x 8 angle iron:

– This larger angle iron sizes provides added strength and stability and is commonly used in heavy construction and industrial projects.

– Ideal for supporting large structures, such as framework, trusses, and bridges.

b. 65 x 8 angle iron:

– This angle iron size offers excellent structural integrity and is also widely used in construction projects.

– Frequently employed for creating sturdy frames, as well as reinforcing steel beams and columns.

c. 25 x 1 8 angle iron:

– This smaller angle iron sizes is commonly used for light-duty projects.

– Ideal for creating brackets, supporting shelves, and constructing small-scale structures.

d. 3/8 x 2 angle iron:

– This smaller yet thicker angle iron provides added strength and durability.

– Often used in manufacturing heavy machinery, trailers, and equipment frames.

e. 65 x 5 angle iron:

– Similar to the 65 x 8 size, this angle iron offers excellent stability and strength.

– Frequently used in building frameworks, fabrication projects, and structural reinforcements.

f. 65 x 6 angle iron:

– This versatile angle iron sizes is suitable for both medium and heavy-duty applications.

– Commonly used for constructing staircases, fences, and gate frames.

g. 2 3×6 angle iron:

– This particular angle iron sizes provide additional structural stability and is frequently used in high-stress environments.

– Ideal for constructing heavy machinery frames, supports, and brackets.

h. 2 x 1/4 angle iron:

– This angle iron size offers good strength and is frequently used in general construction.

– Suitable for creating frameworks, supports, and braces in various projects.

i. 1/4 x 6 angle iron:

– This angle iron sizes are commonly used for lighter duty applications.

– Ideal for creating decorative elements, in addition to providing stability to smaller structures.

g. 1/4 x 1/2 angle iron:

– This smaller and thinner size is often used for light-duty applications.

– Suitable for creating brackets, corner supports, and small-scale framing.

Conclusion

Angle irons continue to be a reliable and versatile choice for professionals in various industries.However, its unrivaled strength, adaptability and economy make it an essential part of construction, fabrication and DIY projects. The wide range of applications discussed highlights the incredible possibilities of angle iron. So the next time you spot an L-shaped steel or iron section, remember its potential to provide strong structural support and enhance the functionality of various projects.