6063 aluminum alloy is widely used in the framework of building aluminum doors, windows, and curtain walls. In order to ensure high wind pressure resistance, assembly performance, corrosion resistance, and decorative performance of doors, windows, and curtain walls, the requirements for the comprehensive performance of aluminum alloy profiles are far higher than the industrial profile standards. Within the composition range of 6063 aluminum alloy specified in the national standard GB/T3190, different values of chemical composition will result in different material characteristics. When the range of chemical composition is large, its performance differences will fluctuate within a large range, resulting in uncontrollable comprehensive performance of the profile. The chemical composition of 6063 aluminum alloy has become an important part of the production of aluminum alloy building profiles

6063 is a representative extrusion alloy with lower strength than 6061, good extrudability, and can be used for complex cross-sectional shapes. It has excellent corrosion resistance and surface treatment properties. And it belongs to the low alloying Al Mg Si series high plasticity alloy. It has many valuable characteristics:

1. Heat treatment strengthening, high impact toughness, and insensitivity to defects.

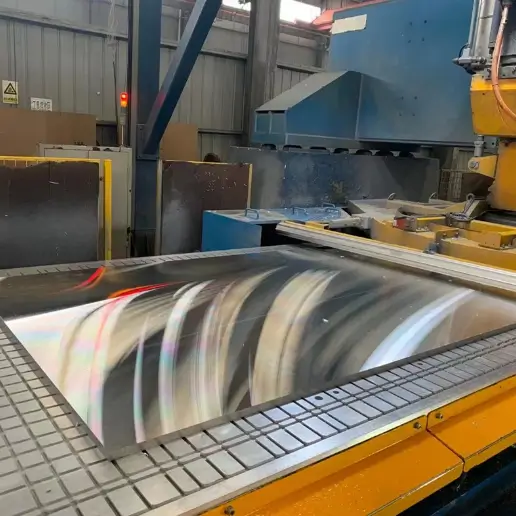

2. It has good thermoplastic properties and can be rapidly extruded into various profiles with complex structures, thin-walled and hollow sections, or forged into forgings with complex structures. It has a wide quenching temperature range and low quenching sensitivity. After extrusion and forging demolding, as long as the temperature is higher than the quenching temperature. It can be quenched by spraying water or penetrating water. Thin walled parts (6 less than 3mm) can also be air quenched.

3. The welding performance and corrosion resistance are excellent, and there is no tendency for stress corrosion cracking. Among the heat treatable reinforced aluminum alloys, the Al Mg Si series alloy is 6063, which has not been found to have stress corrosion cracking phenomenon.

4. The surface after processing is very smooth and easy to anodize and stain. Its disadvantage is that if it is aged at room temperature for a period of time after quenching, it will have a negative impact on strength (parking effect).

Within the composition range of 6063 aluminum alloy specified in the national standard GB/T3190, different values of chemical composition will result in different material characteristics. When the range of chemical composition is large, its performance differences will fluctuate within a large range, resulting in uncontrollable comprehensive performance of the profile. Therefore, optimizing the chemical composition of 6063 aluminum alloy has become the most important step in producing high-quality aluminum alloy building profiles. The role of alloying elements and their impact on performance. 6063 aluminum alloy is a medium strength heat treatable strengthening alloy in the AL Mg Si system, with Mg and Si being the main alloying elements. The main task of optimizing chemical composition is to determine the percentage content of Mg and Si.

6063 aluminum coil is widely used in automotive components, mainly for manufacturing the overall contour of car bodies and other automotive components. This material has excellent weldability, corrosion resistance, heat treatment strengthening, and high impact toughness. The application of lightweight material aluminum alloy can reduce vehicle weight, reduce fuel consumption, and ultimately achieve the goal of energy conservation and emission reduction. At present, aluminum car bodies hold an advantageous position in the world automotive manufacturing industry. 6063 aluminum coil, as an Al Mg Si series high plasticity alloy, has gained greater application in the automotive manufacturing market due to its many excellent characteristics.