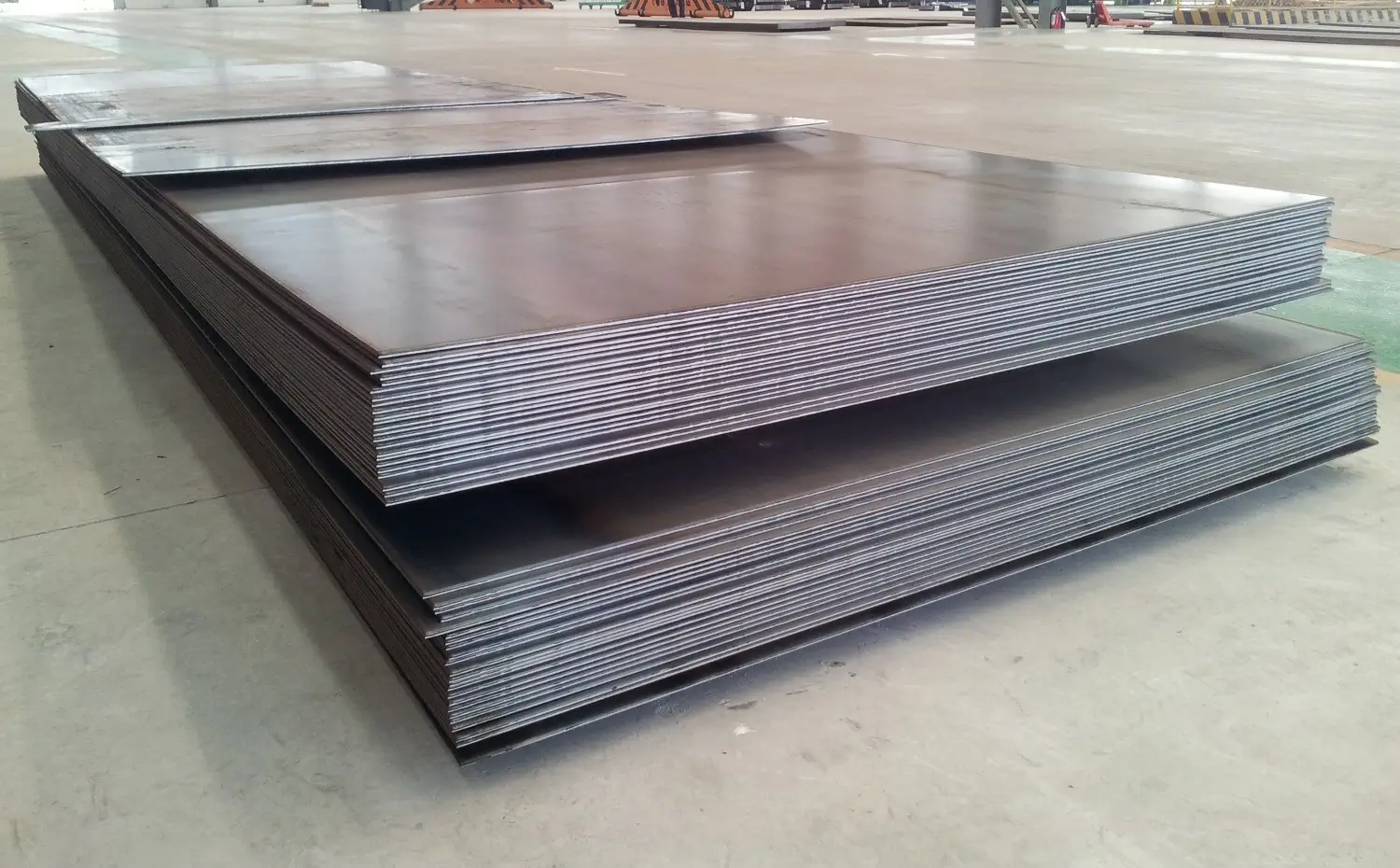

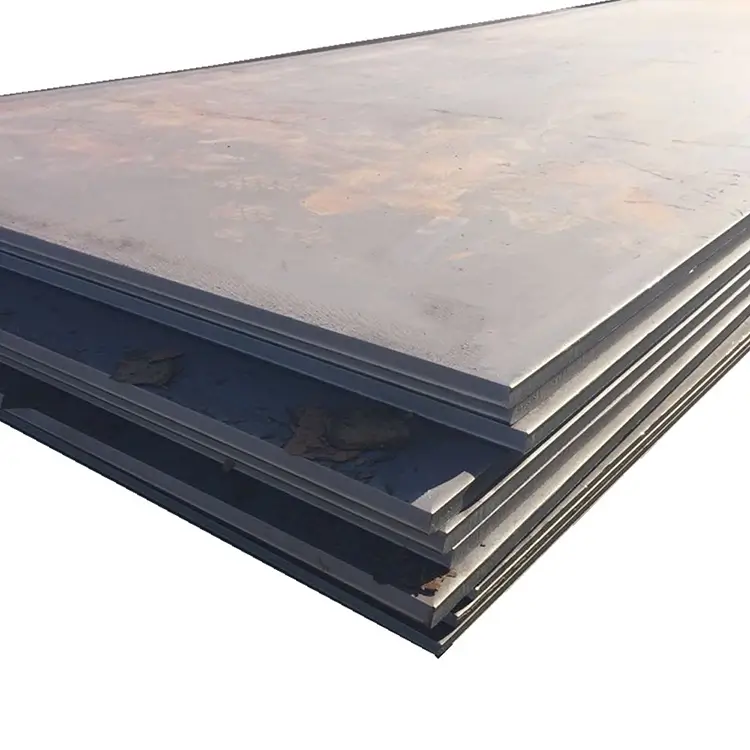

| Product name | Carbon Steel Plate |

|---|---|

| Grade | Q195、Q215、Q235、Q255、Q275、Q345、Q355、SS400、ST37、ST52、S235JR、a36、s235jr etc. |

| Standard | JIS,AISI,ASTM,GB,DIN,BS,BV,etc. |

| Length | 4m-12m or as required by customer |

| Width | 50MM ~ 2200MM or as required by customer |

| Thickness | 0.2mm-3.0mm or as required by customer |

| Surface treatment | Clean, sand blast, spray paint according to customer requirements |

| Technology | Hot rolling, cold rolling |

| Application | Widely used in machinery, metallurgical machinery, coal industry, mining machinery, environmental protectionMachinery, feeder, container, tipper body, sieve plate, elevator, fender, gear, tool and other industries |

| Delivery time | 7 to 15 days after receiving the retainer |

Part 1 Product Description

Carbon Steel Sheet is divided into cold-rolled and hot-rolled steel sheets, and the recrystallization temperature is the distinguishing point. The hot-rolled sheet has poor toughness and surface smoothness, and the price is low, while the cold-rolled sheet has good stretchability and toughness, but the price is more expensive. The cold-rolled sheet is cold-rolled, and the surface has no oxide skin and is of good quality. The hot-rolled sheet is processed by hot rolling, and the surface has an oxide scale, and the thickness of the sheet is poor.

After heat treatment, hot rolled steel plate will have high hardness and good wear resistance. The hardness of hot rolled steel plate in annealed state is moderate and it has good machinability. The hot rolled steel plate has excellent processing technology, good molding and easy welding.According to the thickness of steel plate, thin steel plate <4 mm (the thinnest 0.2 mm), medium thick steel plate 4~60 mm, extra thick steel plate 60~115 mm.The width of the sheet is 500~1500 mm; The width of the thickness is 600~3000 mm.

Part 2 Advantages of carbon steel plate

1. After heat treatment, the hardness and wear resistance can be improved.

2. When annealing, the hardness is appropriate and the cutting ability is good.

3. Its raw materials are very common, so it is easy to find, so the production cost is not high.

A carbon steel plate has usually been considered as the steel that does not contain much alloy steel elements, also named as mild steel. Generally, elements are C, Mn, P, S, Si, besides these, there are no minimum limits for elements of Al, Cr, Ni, Mo, V, etc.Carbon steel plates are available in different grades depending on the carbon content and strength.As the content of Carbon increase, the steel plate hardness increases.

Part 3 classification

1.Low carbon steel plate

For carbon content 0.06% to 0.25%, also we call it mild steel plate.

2.Medium carbon steel plate

C content from 0.25% to 0.55%.

3.High carbon steel plate

0.55% to 1.0%, also called hard steel plate.

Low carbon steel is the most common form, and it’s very malleable and ductile. Medium carbon steel balances ductility as well as strength for excellent wear resistance. High carbon steel is exceptionally strong, while ultra-high carbon steel can be tempered to even greater hardness but no malleability.

As the percentage of carbon gets larger, steel can become harder and stronger through heat-treating. Carbon steel is usually heated to change the mechanical properties of steel, usually ductility, hardness, strength, and resistance of impact. Increasing the carbon content of carbon steel makes it harder and stronger, but reduces the steel’s ability to be welded, making it more brittle.

Carbon steel plate is most often used for structural purposes such as buildings, yet it has the flexibility to be worked into ornate designs. Low carbon steel sheet (wrought iron) is typically used for fences, chain links, gates, and railings. Structural steel (medium carbon steel) is used in cars, refrigerators, washing machines, buildings, and bridges. The steel sheets are normally made up of medium carbon steel.